Yamaha Electric Kettle

Background

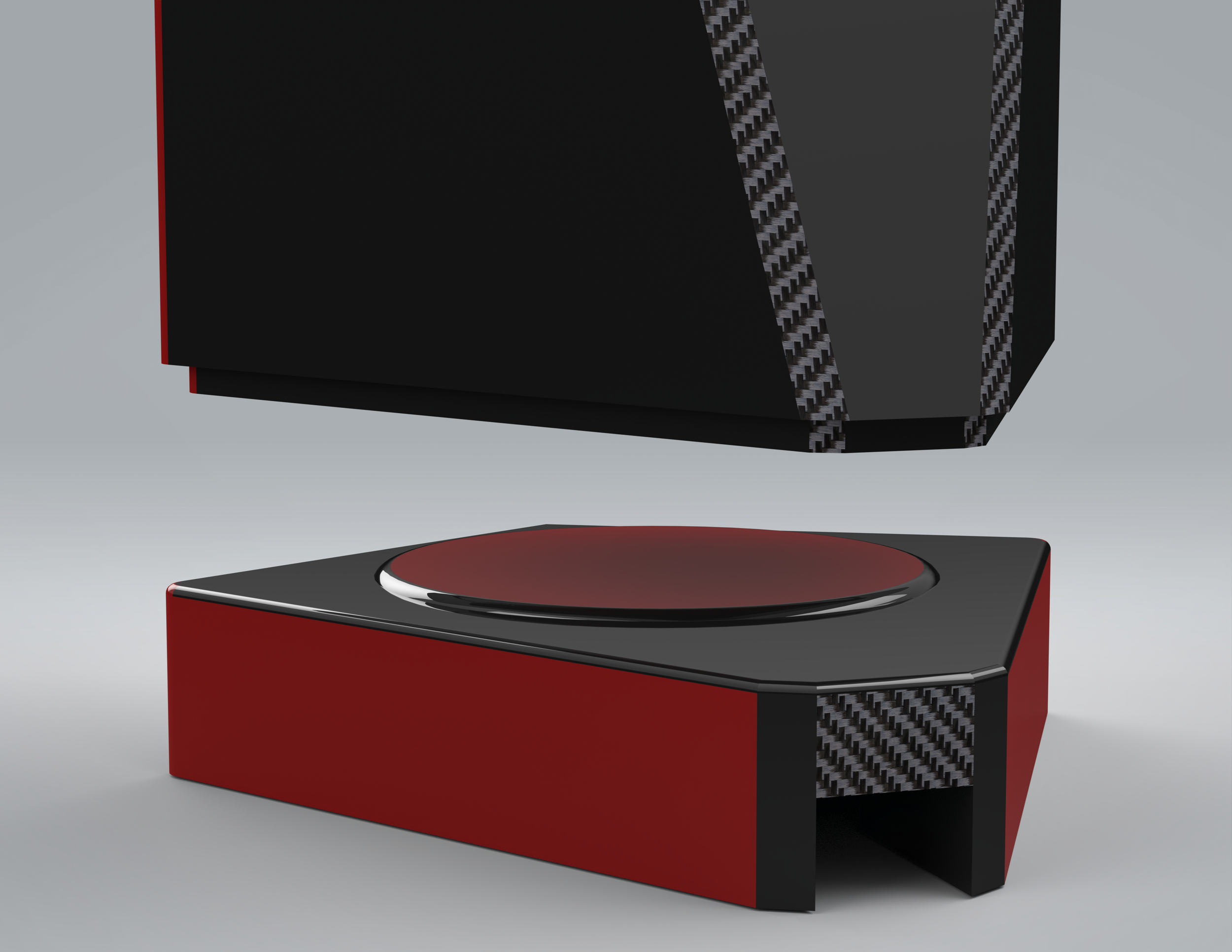

A product redesign project, aimed at form study and brand language understanding. Our team chose to redesign a “breakfast set” based on Yamaha Motorsport theme.

Credits: Valerie Villanueva, Michael Chen

User study results

Intuitive labels are necessary to guide the user

Material and finish selection is important

Product description should include the functionality of the kettle

Geographical differences (US vs EU vs Asia style)

Market research takeaways

There are major differences between kettles on the US market and Japan market.

US kettles lack many safety features found on Japanese kettles, dangerous when there are pets or children around.

Huge capacity is a total waste of water and energy, rarely do people actually use the whole 1.5L+ of water.

Current US market trend is to have LEDs in the kettle.

Boiling tea/coffee inside the kettle is bad for the inner wall, especially when users tend to not clean the kettle often, potential hygiene issue.

Thought process

Based upon the Tiger PCF-G060-W kettle that I used for many years, the concept took the extraordinary performance and reliability of the Tiger kettles and created an aggressive, modern shell. The concept features a multi-lay plastic body, a carbon fiber handle with Yamaha’s signature logo embedded within, and a matching wireless power base. I was never a fan of the traditional style electric kettle power base, difficult to plug the kettle in, also always seemed a few drops of water can set off a fire. I came across the Ki Cordless Kitchen standard while researching, the 2.2kW of power delivery opened up many potentials to my design. I carried the spill proof and steam-less design over from the original Tiger kettle, the 800ml capacity is plenty for single person use.

Features

800ml capacity

Wireless power base

Spill proof

Steamless

One touch power button

Light weight 0.8Kg

225mm x 93mm x 103mm

Afterthought

It was clear to me after the model was made that this concept introduces many difficulties on the manufacturing end, I was only able to achieve a decent 3D print after 4 failures. The lid especially, was too small to fit all the desired features. Nevertheless, this project challenged my creativity and made me realize the importance of model making. Afterall, pretty rendering only get you so far.